Here you will find all the panels already invented. And those yet to be invented

We can entertain you for hours about the countless advantages of using sandwich and honeycomb panels. About their properties and characteristics, their lightness, their sustainability. About why they are used in countless applications in so many industries around the world. We could also go on about affordability, speed of delivery and professionalism in the relationship, but we would be doing ourselves a disservice by telling you what any other player in the industry is capable of.

Instead, we want to talk to you about materials, dimensions, workmanship, colours and finishes. We combine each of these elements with the others, creating the panel that meets the requirements of your project. Especially when it does not exist.

We listen to the request, we often already have the answer. In all other cases, we design the innovative product

Ideas become facts

In-house R&D

laboratories

fire certified

products

in-house machining

different finishes

between cores and skins

fire certifications

The elements for a multitude of different panels

The great capacity for combination and customisation across a boundless range of sectors distinguishes us from others, and the products are tested and certified in all variants, for every standard of the sector for which they are intended.

Different materials, characteristics and performance for the same result

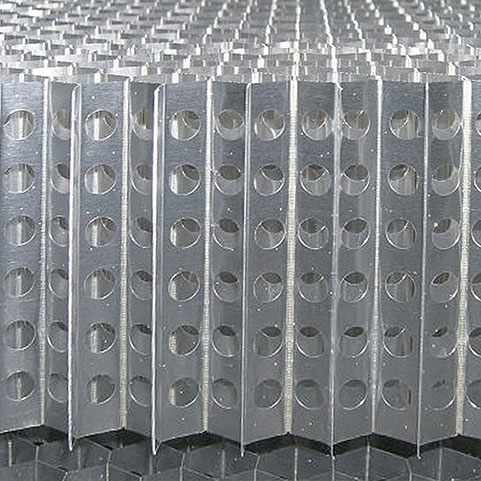

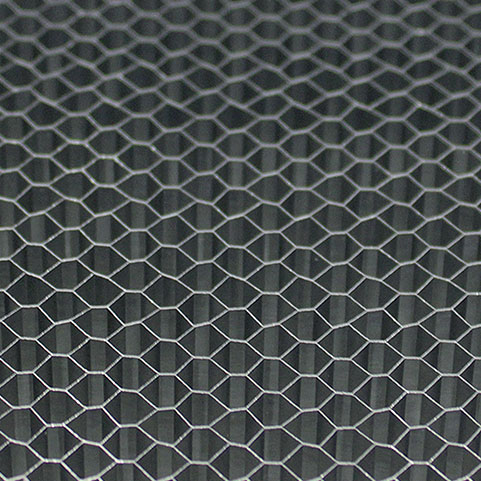

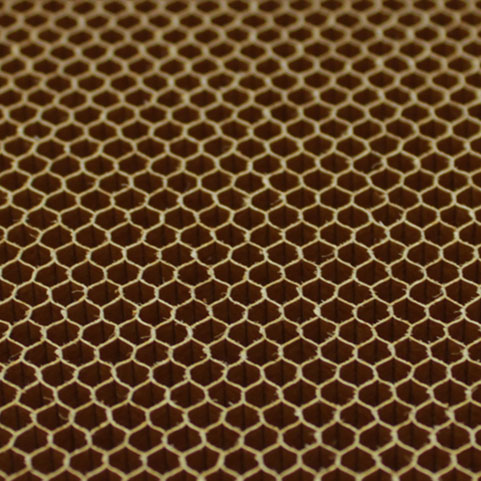

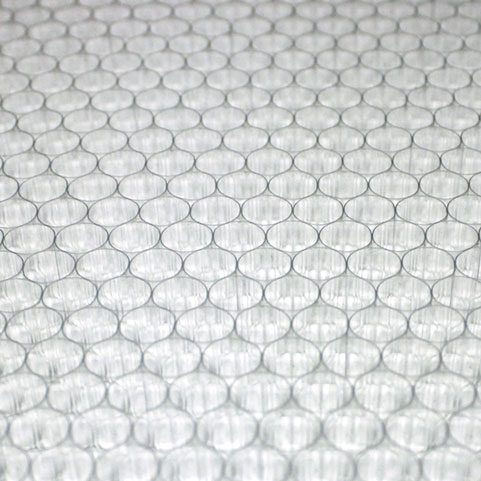

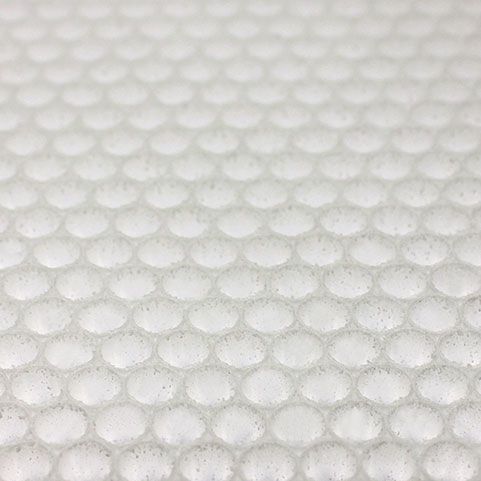

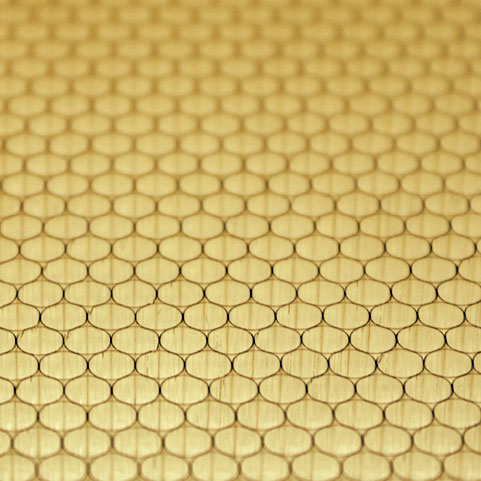

CORES

SKINS

Aluminium

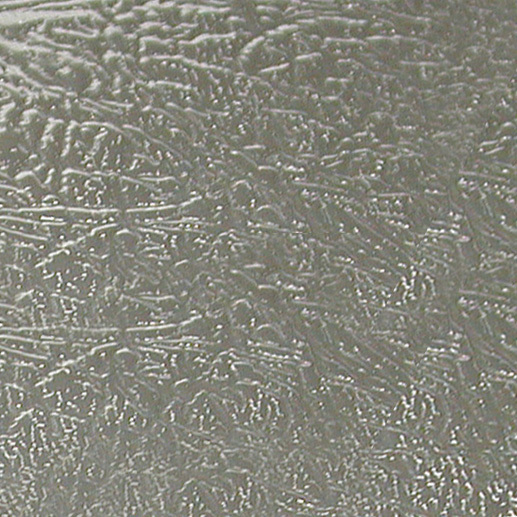

Fiberglass

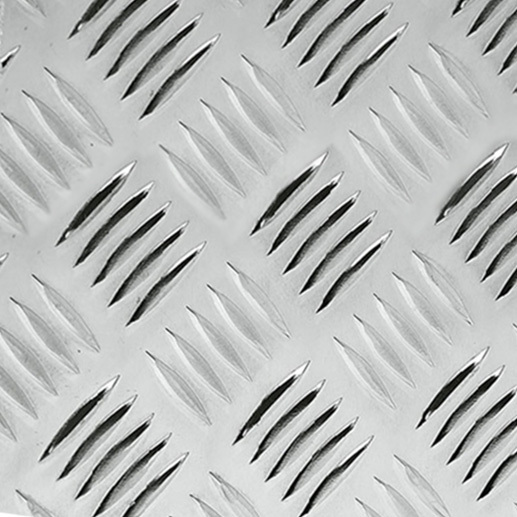

Antiskid aluminium

Decorative stainless steel

Plastic laminate

Marine plywood

Finishes, because looks matter

ALU EXPERIENCE

Range of aluminium finishes, applied directly to the core of the panel, without the need for additional skins/layers. Panels can be finished with edging and inserts for fixing.

Gross

Painted

Surtec 650 treatment

Mirror

Mirror

Corten

PLUS EXPERIENCE

Range of finishes in different materials, applied on standard panels. Panels can be finished with edging and inserts for fixing. The best option for those seeking a special finish while maintaining the lightness and minimum thickness of the panels.

HPL

Solid Surface

Marble

Concrete

Machining, the shape that distinguishes

We are specialists in designing and testing combinations of different cores and skins, but our work is only complete once we have given shape and finish to each panel. Customised workmanship, with special and sought-after specifications. We follow the indications of designers, technicians, architects and technical offices, whether for single numbers, small samples or small - medium - large batches.

Cutting

Shaping

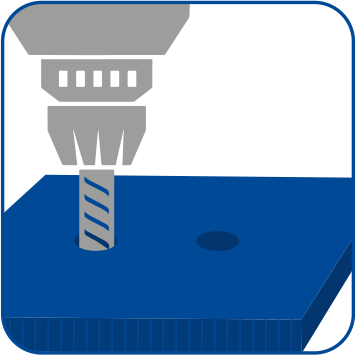

Drilling

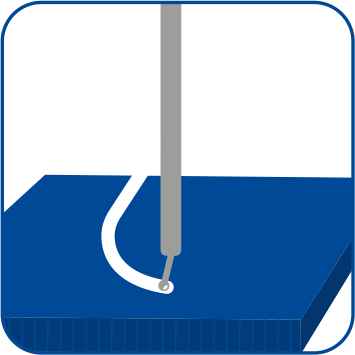

Routing

Folding technique

Edging

Surtec 650 treatment and paintings

Serigraphy and printing

Joining and fixing