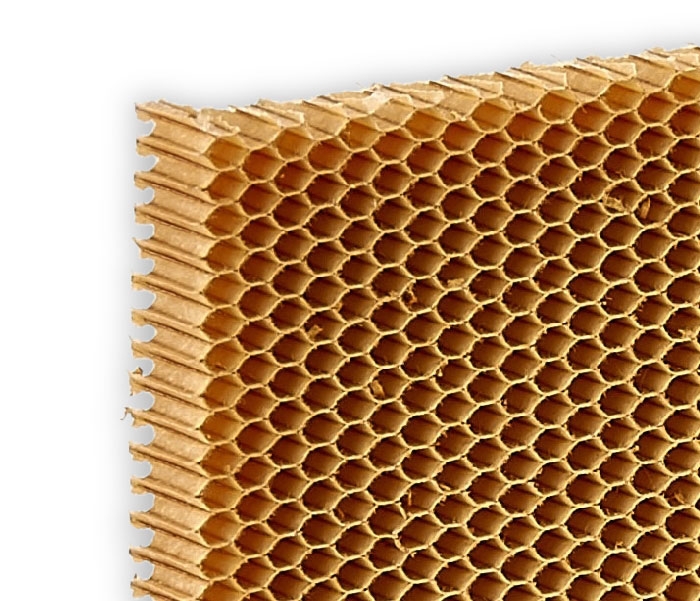

Nomex® honeycomb is a non-metallic, very light and strong product

Made of aramid paper impregnated with phenolic resin, Nomex® has a good electrical insulation capacity and is appreciated for its special lightweight and extreme rigidity features.

The range includes two types of product depending on use:

- industrial;

- aeronautical.

Nomex commercial

Good electrical insulation capacity combined with lightness and rigidity make Nomex® honeycomb a first-class reinforcement.

It is manufactured from aramid paper impregnated with phenolic resin.

Nomex aereonautical

Our clients can choose between commercial and aeronautical grade nomex.

Nomex® is the structural reinforcement of choice for applications in the marine, railway, automotive, military and aeronautical sectors.

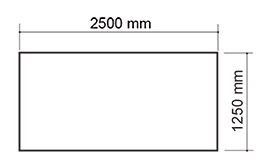

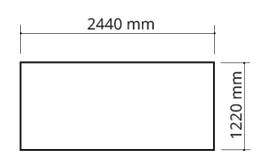

Dimensions

Applications

Technical datasheet

Honeycomb core’s properties |

|||||||||||||

|

Compression bare Strength |

L-direction |

W-direction |

|||||||||||

|

strength |

modulus |

strength |

modulus |

||||||||||

|

Cell size mm |

Density kg/m3 |

(μm) |

min |

typ |

min |

typ |

min |

typ |

min |

typ |

min |

typ |

|

|

Hexagonal |

3,2 |

29 |

(38) |

0.54 |

0.80 |

0.52 |

0.62 |

22 |

27 |

0.28 |

0.38 |

12 |

16 |

|

Hexagonal |

3,2 |

48 |

(51) |

1.90 |

2.10 |

1.16 |

1.32 |

38 |

48 |

0.62 |

0.72 |

24 |

30 |

|

Hexagonal |

3,2 |

64 |

(51) |

3.70 |

4.50 |

1.48 |

1.78 |

50 |

64 |

0.82 |

0.97 |

30 |

38 |

|

Hexagonal |

3,2 |

64 |

(76) |

3.10 |

3.90 |

1.60 |

1.90 |

60 |

68 |

0.94 |

1.05 |

38 |

44 |

|

Hexagonal |

3,2 |

80 |

(76) |

4.70 |

5.50 |

1.95 |

2.35 |

68 |

80 |

1.05 |

1.25 |

38 |

48 |

|

Hexagonal |

3,2 |

96 |

(76) |

6.60 |

7.44 |

2.45 |

2.80 |

86 |

96 |

1.42 |

1.68 |

56 |

68 |

|

Hexagonal |

3,2 |

123 |

(76) |

10.00 |

11.80 |

2.90 |

3.35 |

98 |

118 |

1.76 |

1.94 |

71 |

84 |

|

Hexagonal |

3,2 |

128 |

(76) |

11.30 |

12.88 |

2.95 |

3.40 |

104 |

128 |

1.78 |

2.05 |

74 |

87 |

|

Hexagonal |

3,2 |

144 |

(76) |

13.20 |

15.20 |

3.05 |

3.50 |

110 |

128 |

1.90 |

2.20 |

80 |

94 |

|

Hexagonal |

3,2 |

200 |

(76) |

23.00 |

26.60 |

3.60 |

4.00 |

120 |

138 |

2.20 |

2.70 |

84 |

98 |

|

Hexagonal |

4.0 |

29 |

(51) |

0.60 |

0.80 |

0.45 |

0.56 |

18 |

26 |

0.26 |

0.34 |

11 |

14 |

|

Hexagonal |

4.0 |

48 |

(51) |

2.26 |

2.68 |

1.06 |

1.20 |

34 |

42 |

0.56 |

0.68 |

22 |

28 |

|

Hexagonal |

4.0 |

64 |

(76) |

3.90 |

4.65 |

1.44 |

1.70 |

48 |

58 |

0.80 |

0.90 |

30 |

40 |

|

Hexagonal |

4.0 |

80 |

(76) |

5.10 |

5.70 |

1.90 |

2.50 |

66 |

78 |

0.98 |

1.26 |

36 |

44 |

|

Hexagonal |

4.0 |

123 |

(102) |

9.30 |

10.80 |

3.40 |

3.85 |

110 |

125 |

1.86 |

2.10 |

58 |

68 |

|

Hexagonal |

4.0 |

128 |

(102) |

10.00 |

11.50 |

3.50 |

3.90 |

115 |

130 |

1.90 |

2.20 |

60 |

70 |

|

Hexagonal |

4.0 |

144 |

(102) |

13.00 |

16.00 |

3.60 |

4.00 |

120 |

135 |

2.00 |

2.40 |

70 |

82 |

|

Hexagonal |

4.8 |

32 |

(51) |

0.90 |

1.15 |

0.58 |

0.76 |

23 |

31 |

0.36 |

0.42 |

16 |

22 |

|

Hexagonal |

4.8 |

48 |

(51) |

2.60 |

2.85 |

0.98 |

1.14 |

34 |

40 |

0.56 |

0.66 |

22 |

28 |

|

Hexagonal |

4.8 |

64 |

(76) |

3.40 |

4.40 |

1.70 |

2.00 |

52 |

64 |

0.92 |

1.14 |

34 |

46 |

|

Hexagonal |

4.8 |

96 |

(76) |

8.40 |

9.00 |

2.26 |

2.56 |

78 |

84 |

1.32 |

1.48 |

46 |

56 |

|

Hexagonal |

4.8 |

96 |

(102) |

7.30 |

8.00 |

2.52 |

2.85 |

88 |

94 |

1.44 |

1.68 |

56 |

64 |

|

Hexagonal |

4.8 |

123 |

(127) |

9.30 |

10.80 |

3.40 |

3.85 |

110 |

125 |

1.86 |

2.10 |

58 |

68 |

|

Hexagonal |

6.4 |

24 |

(51) |

0.54 |

0.70 |

0.34 |

0.52 |

14 |

20 |

0.18 |

0.26 |

11 |

14 |

|

Hexagonal |

6.4 |

32 |

(51) |

0.80 |

1.06 |

0.54 |

0.76 |

22 |

32 |

0.30 |

0.40 |

12 |

20 |

|

Hexagonal |

6.4 |

50 |

(76) |

2.15 |

2.60 |

1.00 |

1.26 |

30 |

44 |

0.56 |

0.72 |

20 |

28 |

|

Hexagonal |

6.4 |

64 |

(76) |

3.40 |

4.60 |

1.54 |

1.92 |

54 |

66 |

0.79 |

1.10 |

32 |

40 |

|

Hexagonal |

9.6 |

24 |

(76) |

0.52 |

0.66 |

0.32 |

0.52 |

13 |

21 |

0.16 |

0.26 |

9 |

14 |

|

Hexagonal |

9.6 |

32 |

(76) |

0.68 |

1.06 |

0.56 |

0.77 |

18 |

30 |

0.29 |

0.38 |

11 |

17 |

|

Hexagonal |

9.6 |

48 |

(76) |

1.80 |

2.20 |

1.15 |

1.30 |

30 |

41 |

0.66 |

0.80 |

20 |

26 |

|

Hexagonal |

12.8 |

32 |

(127) |

0.75 |

0.95 |

0.46 |

0.56 |

16 |

20 |

0.26 |

0.30 |

9 |

12 |

|

Hexagonal |

12.8 |

64 |

(127) |

2.80 |

3.40 |

1.60 |

1.82 |

52 |

64 |

0.88 |

1.15 |

26 |

36 |

|

Hexagonal |

19.2 |

24 |

(127) |

0.50 |

0.62 |

0.50 |

0.60 |

11 |

16 |

0.22 |

0.28 |

9 |

11 |

|

Hexagonal |

19.2 |

32 |

(127) |

0.70 |

0.92 |

0.60 |

0.80 |

18 |

28 |

0.32 |

0.48 |

14 |

22 |

|

Over-expanded |

4.8 |

29 |

(51) |

0.60 |

0.85 |

0.31 |

0.42 |

9 |

14 |

0.32 |

0.4 |

14 |

24 |

|

Over-expanded |

4.8 |

48 |

(51) |

2.30 |

2.80 |

0.66 |

0.74 |

18 |

24 |

0.72 |

0.82 |

36 |

44 |

|

Over-expanded |

4.8 |

64 |

(51) |

3.80 |

4.60 |

0.72 |

0.84 |

22 |

26 |

0.90 |

1.04 |

48 |

56 |

|

Over-expanded |

6.4 |

48 |

(51) |

2.30 |

2.80 |

0.66 |

0.74 |

15 |

22 |

0.72 |

0.78 |

33 |

42 |

|

Over-expanded |

6.4 |

56 |

(51) |

2.80 |

4.10 |

0.74 |

0.94 |

18 |

24 |

0.78 |

0.92 |

36 |

46 |

|

Over-expanded |

4.8 |

64 |

(51) |

3.20 |

4.50 |

0.82 |

0.92 |

21 |

26 |

0.92 |

1.02 |

40 |

56 |

Tolerance - density +/- 16%

Honeycomb core’s properties |

|||||

|

|

Compression |

L-Shear |

W-Shear |

||

| Cell size mm | Density kg/m3 | N/mm2 | N/mm2 | N/mm2 | |

|

Hexagonal |

3,2 |

48 |

1,90 |

1,16 |

0,62 |

|

Hexagonal |

3,2 |

64 |

3,10 |

1,48 |

0,82 |

|

Hexagonal |

3,2 |

80 |

4,70 |

1,95 |

1,05 |

|

Hexagonal |

3,2 |

96 |

6,60 |

2,45 |

1,42 |

|

Hexagonal |

3,2 |

128 |

11,30 |

2,95 |

1,78 |

|

Hexagonal |

3,2 |

144 |

13,20 |

3,05 |

1,90 |

|

Hexagonal |

4,0 |

29 |

0,60 |

0,45 |

0,26 |

|

Hexagonal |

4,0 |

80 |

5,10 |

1,90 |

0,98 |

|

Hexagonal |

4,8 |

32 |

0,90 |

0,58 |

0,36 |

|

Hexagonal |

4,8 |

48 |

2,60 |

0,98 |

0,56 |

|

Hexagonal |

4,8 |

64 |

3,40 |

1,70 |

0,92 |

|

Hexagonal |

4,8 |

80 |

6,00 |

1,95 |

1,10 |

|

Hexagonal |

4,8 |

96 |

7,30 |

2,26 |

1,32 |

|

Hexagonal |

6,4 |

24 |

0,54 |

0,34 |

0,18 |

|

Hexagonal |

6,4 |

32 |

0,80 |

0,54 |

0,30 |

|

Hexagonal |

6,4 |

48 |

2,05 |

1,00 |

0,56 |

|

Hexagonal |

6,4 |

64 |

3,40 |

1,54 |

0,79 |

|

Hexagonal |

9,6 |

24 |

0,54 |

0,34 |

0,18 |

|

Hexagonal |

9,6 |

32 |

0,68 |

0,56 |

0,29 |

|

Hexagonal |

9,6 |

48 |

1,80 |

1,15 |

0,66 |

|

Over expanded |

4,8 |

29 |

0,60 |

0,31 |

0,32 |

|

Over expanded |

4,8 |

48 |

2,30 |

0,60 |

0,72 |

|

Over expanded |

4,8 |

64 |

3,80 |

0,72 |

0,90 |

|

Over expanded |

4,8 |

72 |

4,00 |

0,75 |

0,92 |

|

Over expanded |

4,8 |

80 |

5,30 |

0,88 |

1,17 |

|

Over expanded |

4,8 |

96 |

6,70 |

0,92 |

1,28 |

|

Over expanded |

6,4 |

48 |

2,30 |

0,60 |

0,72 |

|

Over expanded |

6,4 |

64 |

3,20 |

0,72 |

0,90 |

Tolerance - density: +/- 16%

Thickness’ tolerance: +/- 0.250 mm

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

IMPORTANT

To allow us to offer you a panel with particular finishes or colors without minimal pigment variations, it is recommended to place an overall order , so that we can plan the production with the rolling mills that will carry out the painting of the sheets in a batch.