The world's leading commercial refrigeration companies use polycarbonate honeycomb

The main application for polycarbonate honeycomb is laminar directional flow ventilation deflectors, ventilated curtains for the commercial refrigeration industry, wind tunnels and climatic chambers.

With polycarbonate honeycomb deflectors, flow efficiency and effectiveness are significantly improved, turbulence is eliminated, and pressure losses, energy consumption and noise are reduced.

The polycarbonate honeycomb also proves to be very versatile in lighting technology. Indeed, it has the ability to channel light beams.

In visual grade, the positioning of the cells is controlled one by one for superior quality. Its processing can generate extra costs.

The standard quality is still a high level product but occasionally it may present defects. Use and performance remain unconditional except for the lighting industry. Lighting customers are requested to always indicate the need for a visual grade quality honeycomb.

Polycarbonate honeycombs with a density of 200 kg/m3 are also excellent shock absorbers for vehicle protection while using lower densities results in lightweight, breathable anti-trauma structures.

CEL Components honeycombs set new standards in energy absorption. In fact, the uniform crushing of the cells absorbs kinetic energy at a constant compression level up to a reduction of 78% of their initial volume. We provide special densities depending on the desired level of energy absorption.

Transparent-coloured polycarbonate can also be used for decorations and special applications.

Technical features

The polycarbonate honeycomb stands out because it is:

- easy to apply;

- customisable;

- waterproof and washable;

- 100% recyclable

We supply two types of polycarbonate:

- Visual grade polycarbonate;

- Standard grade polycarbonate

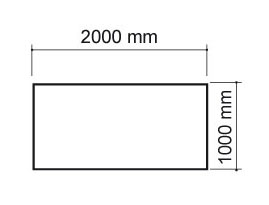

Dimensions

Applications

Technical datasheet

Honeycomb core’s properties |

standard |

on request |

|||

|

Type |

3, 5-90 |

6, 0-70 |

2, 5-110 |

4, 0-80 |

7, 0-70 |

|

Cell size mm |

3, 5 |

6, 0 |

2, 5 |

4, 0 |

7, 0 |

|

Colour |

grey • white • trasparent • black |

||||

|

Density kg/m3 |

90 |

70 |

110 |

80 |

70 |

|

Compressive strength MPa |

2, 8 |

1, 9 |

3, 6 |

2, 2 |

1, 8 |

|

Compressive modulus MPa |

115 |

95 |

155 |

106 |

95 |

|

Shear strength MPa |

1, 3 |

1, 0 |

1, 5 |

1, 1 |

1, 0 |

|

Shear modulus MPa |

22 |

19 |

25 |

21 |

19 |

|

Effective temperature range °C |

from -40 to +110 |

||||

|

Thickness mm |

from 3 to 300 |

||||

|

Maximum length mm |

3000 |

||||

|

Maximum Width mm |

1350 |

||||

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

IMPORTANT

To allow us to offer you a panel with particular finishes or colors without minimal pigment variations, it is recommended to place an overall order , so that we can plan the production with the rolling mills that will carry out the painting of the sheets in a batch.