Finishes, because the eye always demands its share

ALU EXPERIENCE, BEAUTIFUL AND ELEGANT

Range of aluminum finishes, applied directly to the panel core, without the need for additional skins / layers. Panels can be finished with edging and inserts for fixing.

Gross

Gray sheets characteristic of aluminum, available with or without primer to facilitate bonding.

Painted

Standard color RAL 9016, different pigments and paint types available depending on the performance required. Anti-scratch and titanium dioxide paints available.

Surtec 650 treatment

The raw aluminum sheet can be treated with SurTec 650 in order to have a surface suitable for gluing, which meets the certifications required in the various aerospace and military sectors.

Mirror

gold version.

Mirror

Silver version.

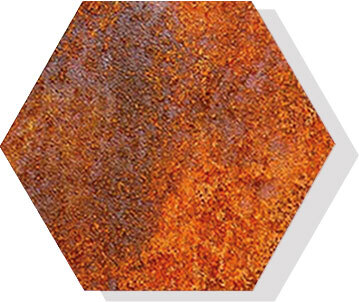

Corten

Orange and corten pattern.

PLUS EXPERIENCE, MINIMUM THICKNESS FOR MAXIMUM EFFICIENCY

Range of finishes in different materials, applied to standard panels. Panels can be finished with edging and inserts for fixing. The best choice for those looking for a special finish while maintaining the lightness and minimum thickness of the panels.

HPL

Surfaces in plastic laminate with finishing on request, also available in scratch-resistant version.

Solid Surface

Resistant material, available in various colors.

Marble

Marble slab applied to the panel, on request.

Concrete

Thin layer of cement applied to the panel, smooth or rough.

Processing, the distinctive shape

We specialize in designing and testing combinations of different cores and skins, but our work is only complete after giving shape and finishes to each panel. Custom processing, with distincst and refined specifications. We follow the guidance of designers, technicians, architects, and technical offices, whether it's for individuals, small samples, or small-medium-large batches.