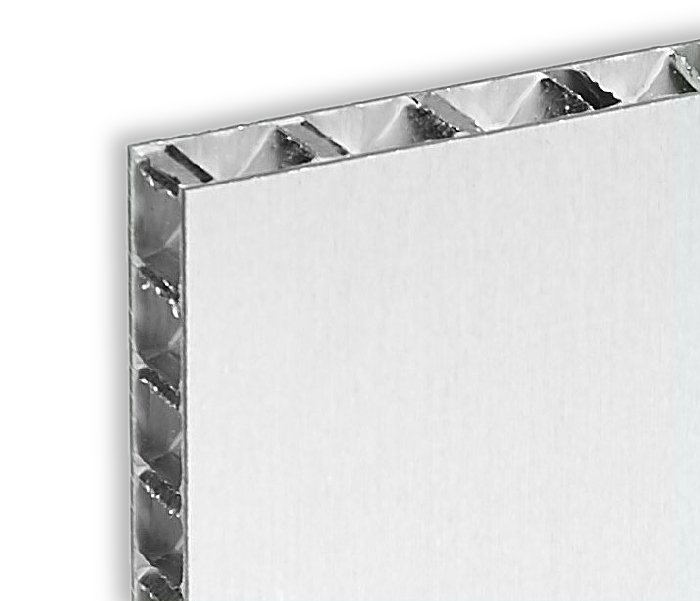

The COMPOCEL® AL FR sandwich panel is a certified panel with skins and core made entirely of aluminium

This is the certified version of the COMPOCEL AL panel that complies with the most stringent regulations for the railway, shipbuilding and construction industries.

Technical features

The COMPOCEL AL FR panel is normally purchased by all those customers who need lightness and excellent reaction to fire performance. The new terminal of Charles de Gaulle Airport in Paris, the new Athens airport and the tower of the Turkish central bank for example, were built with our COMPOCEL AL FR panels.

.png)

A - ALUMINIUM SKINS

Thickness mm: 0,5 - 0,8 - 1 (standard)

B - STRUCTURAL ADHESIVE

C - CORE IN ALUMINIUM HONEYCOMB

Aluminium honeycomb (Alloy series 3000*)

with hexagonal cells

Diameter: Ø1/4”, Ø3/8”, Ø1/2”, Ø3/4”

Thickness Foil: from 50 to 70 microns

* To Aluminium alloy series 3000 belong: Aluminium alloy 3003, Aluminium alloy 3005, Aluminium alloy 3103, Aluminium alloy 3104.

Dimensions

Painting

The COMPOCEL® AL FR Sandwich Panel has been certified with different types of powder or liquid paint to suit various stylistic, aesthetic and environmental requirements.

Maintenance

The panel's user manual indicates the conditions under which the material must be stored and preserved optimally. Among the most important factors affecting panel storage are: storage temperature, handling, exposure to light and weather.

Particular attention must be paid to the presence of protective films that may be difficult to remove when subjected to atmospheric agents or after prolonged storage.

The panel is easy to clean and degrease, but the use of acidic substances or abrasive components is not recommended as they could compromise its aesthetic qualities.

Recycling

The COMPOCEL AL® panel is 95% recyclable as it consists of 95% aluminium, which can be melted down and reused several times.

Applications

Technical datasheet

Technical data sheet for standard panels (dimensions, materials and special finishes on request) |

|||||||

| TECHNICAL CHARACTERISTICS OF PANEL | |||||||

panel size mm |

standard 1250 x 2500 / 1250 x 3000 / 1500 x 3000; On request up to 2000 x 7000 |

||||||

thickness’ tolerance mm |

± 0,3 |

||||||

dimension’s tolerance mm |

± 30 |

||||||

planarity *** mm/m |

+/-1 |

||||||

skins’ thickness mm |

from 0,5 to 5,0 |

||||||

skin alluminium alloy |

1000 series, 3000 series, 5000 series |

||||||

honeycomb alluminium alloy |

3000 series, 5000 series |

||||||

thickness of honeycomb foil μm |

50 and 70 |

||||||

diameter of honeycomb Ø = mm |

from 3 to 19 |

||||||

honeycomb density Kg/m³ |

from 20 to 163 |

||||||

adhesive |

two-components polyurethane adhesive/thermoplastic film/ epoxy film/ |

||||||

skin characteristics |

rough/primer/polyester/PVDF/ anodised |

||||||

| PANEL PHISIC AND MECHANIC PERFORMANCES | |||||||

type panel (some examples) - Panel Thickness mmtype panel (some examples) - Skin Thickness mm |

6 |

10 |

15 |

10 |

15 |

20 |

25 |

0,5 + 0,5 |

1,0 + 1,0 |

||||||

panel weight ‡ Kg/m2 |

3,8 |

4,0 |

4,3 |

6,7 |

7,0 |

7,3 |

7,6 |

compressive stabilised strength MPa ** ‡

|

2,9 |

||||||

maximum load ** ‡ ASTM C 393 † N |

190 |

340 |

520 |

600 |

1.000 |

1.350 |

1.700 |

deflection at maximum load ‡

|

14 |

8 |

6 |

8 |

6 |

4 |

3 |

skins E Elastic Modulus Mpa |

68.000 - 70.000 |

||||||

moment of inertia I ** mm4/m |

7.600 |

22.000 |

52.000 |

40.000 |

98.000 |

181.000 |

288.000 |

average resistance to peeling ** ‡

|

> 280 N/76 mm or 40 Nmm/mm |

||||||

maximum service temperature ** °C |

- 40 / + 60; on request + 80 / + 100 / + 150 |

||||||

thermal expansion coefficient ** °C-1 |

2,3 x 10-5 |

||||||

** Tested by Internal Laboratory

*** Approximate value

† Sample dimension with 4 support points (L, W) 540x50mm;

distance among the lower points 500mm, distance among the upper points 250mm

‡ Values for a panel with a honeycomb core of Ø6 56kg/m3 (Ø 1/4”)

COMPOCEL AL FR- FIRE REACTION - CLASSES AND CERTIFICATIONS

Certified version COMPOCEL AL FR must be required while asking for a quotation might have a price surcharge due to certified materials.

| FIRE REACTION | |||

| SECTOR | NORM | CERTIFICATION | DESCRIPTION |

|

SHIPBUILDING |

FTP CODE 2010 3.18a

0407 |

LOW FLAMESPREAD MOD. B. Certification Nr.

|

COMPOCEL AL FR

|

|

|

U.S. Coast Guard

|

MOD. B.

|

COMPOCEL AL FR

|

|

FTP CODE 2010 3.64

|

BULKHEAD C. CLASS DIVISION

|

COMPOCEL AL FR

|

|

|

BUILDING |

UNI EN 13501-1 |

A2 s1 d0 COMPOCEL AL FR NON- COMBUSTIBLE

|

COMPOCEL AL FR, Aluminium honeycomb panel A2 - NON- COMBUSTIBLE |

|

BUILDING |

UNI EN 13501-1 |

A2 s1 d0

NON- COMBUSTIBLE

|

COMPOCEL AL FR

|

|

BUILDING FLOORS |

UNI EN 13501-1 |

A2fl s1 d0 NON- COMBUSTIBLE

|

COMPOCEL AL FR,

Aluminium honeycomb panel

A2 - Incombustible |

|

BUILDING |

UNI EN 13501-1 |

B s1 d0 LOW FLAME SPREAD

|

COMPOCEL AL FR Aluminium honeycomb panel

|

|

BUILDING FLOORS |

UNI EN 13501-1 |

Bfl s1 d0 LOW FLAME SPREAD

|

COMPOCEL AL FR, FLOOR, ALURIS, Aluminium honeycomb panel

|

|

BUILDING |

NF P92-501 |

M1

|

NOT FLAMABLE |

|

RAILWAY VEHICLES |

UNI EN 45545-2 |

HL3 (HAZARD LEVEL)

|

COMPOCEL AL FR Aluminium honeycomb panel

|

| COMPLY WITH AMERICAN STANDARDS | ||||

|

ASTM C67-M18 Water Absorption

|

ASTM E72-15 Strength-Transverse load |

ASTM C297 M-16 Flatwise tensile strength |

ASTM E84-17 Flamespread |

TAS 201 Impact and Cyclic Wind Pressure |

Honeycomb core’s properties |

50 Microns |

|||

Type |

ALUMINIUM ALLOY 3003/3005/3103/3104 |

|||

Ø honeycomb in mm |

6 |

9 |

12 |

19 |

Ø honeycomb in inches |

1/4" |

3/8" |

1/2" |

3/4" |

Density Kg/m3 |

56 - 59 |

39 - 40 |

29 - 30 |

20 - 21 |

Compressive stabilised strength MPa |

3,0 - 3,5 |

1,4 - 1,95 |

0,8 - 0,95 |

0,4 - 0,6 |

Honeycomb core’s properties |

70 Microns |

|||

TipoType |

ALUMINIUM ALLOY 3003/3005/3103/3104 |

|||

Ø honeycomb in mm |

6 |

9 |

12 |

19 |

Ø honeycomb in inches |

1/4" |

3/8" |

1/2" |

3/4" |

Density Kg/m3 |

80 - 83 |

54 |

40 - 42 |

27 - 29 |

Compressive stabilised strength MPa |

4,3 - 4,6 |

2,5 - 2,6 |

1,41 - 1,5 |

0,85 - 0,9 |

A Richiesta e con sovrapprezzo la versione certificata COMPOCEL AL FR

La richiesta di prodotti certificati deve essere tassativamente formulata in fase di offerta ed è soggetta a sovrapprezzo.

| CLASSI PER REAZIONI AL FUOCO | |||

| SETTORE | NORMA | CERTIFICAZIONE | DESCRIZIONE |

|

NAVALE |

FTP CODE 2010 3.18a

0407 |

BASSA PROPAGAZIONE MOD. B. Certificato N.

|

COMPOCEL AL FR

|

|

|

U.S. Coast Guard |

MOD. B.

|

COMPOCEL AL FR

|

|

FTP CODE 2010 3.64

|

PARATIA C. CLASS DIVISION

|

COMPOCEL AL FR

In conformità con la direttiva MED Articolo no 2010, Allegato 1

|

|

|

EDILIZIA |

UNI EN 13501-1 |

A2 s1 d0

NON COMBUSTIBILITA’

|

COMPOCEL AL FR, FLOOR, ALURIS,

Pannello alveolare in alluminio

A2 - NON COMBUSTIBILE |

|

EDILIZIA FACCIATE VENTILATE |

UNI EN 13501-1 |

A2 s1 d0

|

COMPOCEL AL FR Pannello alveolare in alluminio A2 – NON COMBUSTIBILE |

|

EDILIZIA - |

UNI EN 13501-1 |

A2fl s1 d0 NON COMBUSTIBILITA’

|

COMPOCEL AL FR, FLOOR, ALURIS, ALUMAN

Pannello alveolare in alluminio

A2 - NON COMBUSTIBILE |

|

EDILIZIA GENERALE |

UNI EN 13501-1 |

B s1 d0 BASSA PROPAGAZIONE

|

COMPOCEL AL FR Pannello alveolare in alluminio

|

|

EDILIZIA - |

UNI EN 13501-1 |

Bfl s1 d0 BASSA PROPAGAZIONE

|

COMPOCEL AL FR, FLOOR, ALURIS, Pannello alveolare in alluminio

|

|

EDILIZIA |

NF P92-501 |

M1

|

NON INFIAMMABILE |

|

FERROVIARIO |

UNI EN 45545-2 |

HL3 (livello di rischio)

|

COMPOCEL AL FR

|

| CONFORME AGLI STANDARD AMERICANI | ||||

|

ASTM C67-M18 Assorbimento

|

ASTM E72-15 Resistenza carico |

ASTM C297 M-16 Resistenza alla |

ASTM E84-17 Propagazione di fiamma |

TAS 201 Test per resistenza forza uragani |

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

IMPORTANT

To allow us to offer you a panel with particular finishes or colors without minimal pigment variations, it is recommended to place an overall order , so that we can plan the production with the rolling mills that will carry out the painting of the sheets in a batch.